|

|||

|

About us | Machinery | NEW | Contact us |

|||

|

|

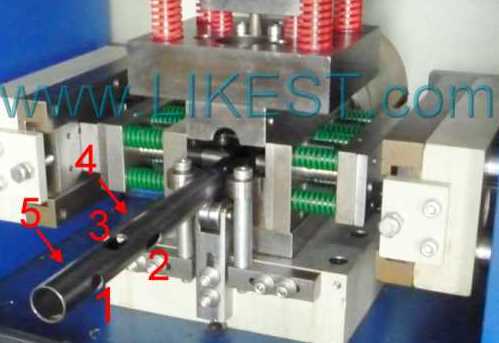

C Channel / U Channel / Z Channel / H BEAM / Round Tube / Square Tube / Rectangle Tube Punching Machine U-3000 -automatic tube punching machine with Loading and Unloading System -Three cylinders 3 independent punching units: from top, left, right -punch 9 different holes on the same tube. And auto tool change: up to 9 punch-tools in one cycle. -auto loader and un-loader -Option: combined with cutting machine / band saw. |

||

|

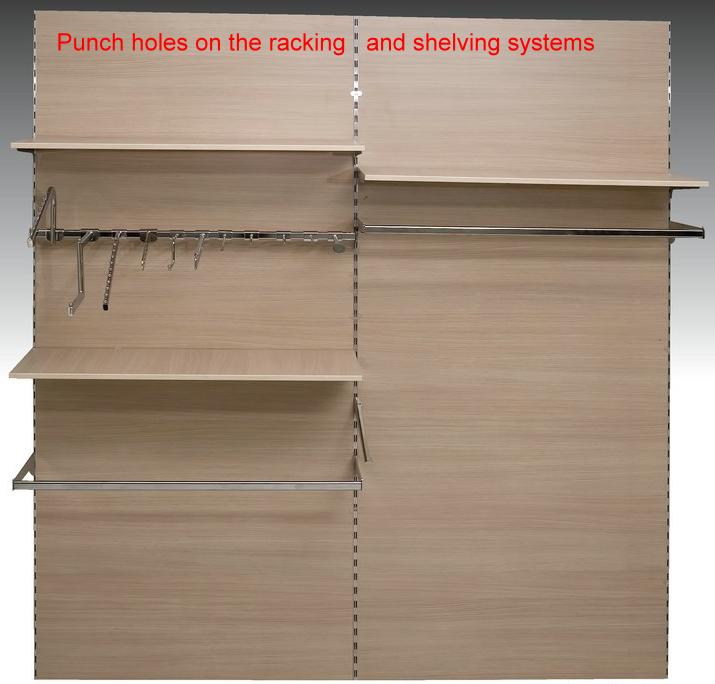

Punched Samples: ( 6 different holes with stamp logo) Video: More Video

Feature: 1. 3 independent punching units: This machine can punch 9 different holes on the same tube 2. Auto Tube Punching Machine with 3 Punching Heads (2 Horizontal and 1 Vertical) + Tube Rotation Servo Motor to punch the holes in the different angles: 3 punch units (from top, left, right) 3. Full automatic punching tool shifting system ( Punching pin changing system): Auto tool change up to 9 punch-tools in one cycle. 4. Auto loader and un-loader : It can be equipped with an automatic warehouse-system for the up loading- and unloading of the bars. 5. Servo controlled 6. Rotation Servo Motor: With Y-Axis [FEED] & B-Axis [Rotate] Servo Motors which can clip the Round Tube and rotate the Round Tube for punching the holes in the different angles. 7. Back Pulling System (combined with Servo Motor): To pull the tube from the other side by the same Servo Motor for punching the last hole which is too close to the tube end. On some of the bars/ tubes, the hole distance can vary for the first and last few holes of one finished bars/ tubes. This system can pull the bars/ tubes from the other side for punching the last hole which is too close to the bars/ tubes end. The Back Pulling System that allows it to punch at the edges of the bars/ tubes material and leaving practically no leftover or crop waste in the stock material, i.e., it will save your raw materials. 8. Carriage rotation system 9. Short length shifter 10. Shielding: It is equipped with a set of safety guards. Related machine - 1 Punching Station, 1 Tube, up to 3 Punches C-3000SL MORE 1 Punching Station, 2 Tubes, up to 3 Punches C-3000SLD 2 independent Punching Stations, 2 Tubes C-3000DL - Automatic tube punching and cutting machine U2-8000-50BSR MORE - Angle Steel Punching Machine MORE - Automatic H-beam / I-beam / W-beam Punching Machine MORE - Flange punching Machine CF120-50D MORE Specifications: - 17 Tons Hydraulic Cylinder * 3 sets (Top / Left / Right) - Three Hydraulic Cylinders Automatic Tube Punching Machine with 3 Punching Heads (2 Horizontal and 1 Vertical) and Rotation Servo Motor (option). - This machine can punch 9 kinds (or 7 kinds or 3 kinds) different holes (or above) on the same profile/channel/tube. Coupled / Combined with a special design patent shifting feature, it is able to punch from 3 to 9 different tool shapes in 3 different directions (vertically and from both horizontal sides). So you can punch DIFFERENT Hole Size and Shape on UPN Channel or any Profile without change the mold. - Option : With Y-Axis [FEED] & B-Axis [Rotate] Servo Motors which can clip the tube & ROTATE the tube to punch the holes in the different angles - Option : It allows to punch at the edges of the tube material and leaving practically no leftover or crop waste in the stock material. - Option : Automatic Loading and Unloading System - With 3 sets Power Press (Punching Device with Hydraulic Cylinder) + Dies + Auto Feeder - FULL automatic punching for C-Channel and TUBES - NC Digital Dual Cylinder Linear Pipe/Tube Punching Machine (Puncturing Machine with Servo Motor) for Rectangle Tube/Round Tube/Circle Tube/Square Tube/Ellipse Tube/Perforation

- Punching Capacity: Hydraulic punching machine with 2 Horizontal Heads and 1

Vertical Head, each having maximum power as follows: - Servo Feed-in Positioner Frame for Material Length: 7000mm (SPECIAL DESIGN OR LONGER TUBES IS WELCOME) for Different variable Lengths of the tubes - Punching Types for Holes: Blind Hole, Through Hole, Perforation APPLICATION : quemadores de gas, wine cellars structures,, Agriculture Structure, Green House, Greenhouse. |

|||